Lean Transformation

Lean is a prevalent concept in today’s

manufacturing and sustainment industries; and

it is often used within the context of Just In

Time production and World Class Manufacturing.

These underlying concepts are not new and derive

from Toyota’s methodology on production.

The lineage can be traced back to Henry Ford and

even to Eli Whitney’s concept of interchangeable

parts. Today, conventional definitions of Lean

classify it as "manufacturing without waste.“

Waste can take the form of material, time, underutilized

machine capacity, and excess inventory.

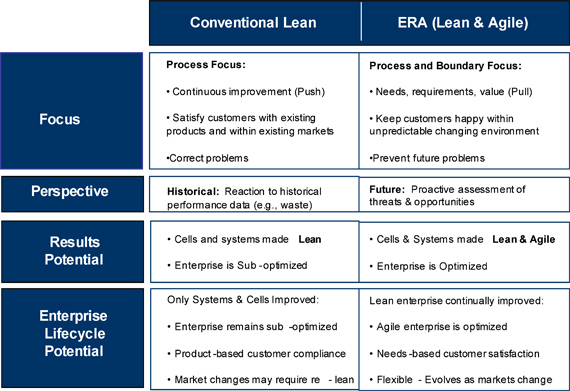

Limitations of Conventional

Lean Techniques – “Leaning”

the organization to eliminate waste is certainly

an important focus for any manufacturing or sustainment

enterprise, but it has its limitations. Conventional

Lean techniques are focused on “problem

correction,” and aimed at continuous improvement;

a worthwhile pursuit when attempting to satisfy

existing customers within existing products and

within existing market parameters. But, what happens

when some combination of those variables change?

ERA™ was designed with inevitable and continuous

change in mind. It is a customer requirements-driven

approach that is designed to keep customers satisfied

in their continuously changing environment. As

a result, we can say that, rather than focusing

on simply correcting problems, ERA™ is focused

on preventing future problems through the proactive

assessment of threats and opportunities.

A Holistic Versus Cellular

Perspective – Conventional Lean techniques

inevitably focus on individual cells and systems

within the enterprise (e.g. IT, manufacturing,

Inventory, distribution …) Unfortunately,

the best case scenario will be that cells and

systems are made lean while the overall enterprise

remains sub-optimized. ERA™ is an approach

to apply holistic thinking and analysis to the

enterprise in such a way that it can be optimized,

rendering it both Lean and Agile. This presents

significant potential for the enterprise to thrive

in its continuously changing environment.

|